Horizontal Terra Cotta Panel with Knight Wall Systems

Horizontal terra cotta panels have been accommodated by all of Knight’s systems. The most common application includes a special vertical carrier rail supplied by the terra cotta manufacturer where the panels are secured to the rail by proprietary clips. This vertical rail is then attached to a Knight system which would be installed in a horizontal orientation (perpendicular to the carrier rail). This will allow for the terra cotta vertical carrier rails to be installed anywhere they are required for proper support.

A challenge that is regularly encountered, but can be accommodated, is the substantial spacing of the vertical carrier rails. Terra cotta manufacturers generally attempt to space their rails as far as possible (up to 48″ on-center), however this generally results in massive wind and dead loads (point loads) being applied to the system to which it is attached. These large point loads can be accommodated with slightly tighter spacing of the supporting system behind. Knight typically recommends 16-gauge rails/girts for these applications.

All guidance provided above assumes typical installation applications in which KWS has observed to be the most common methods. Every project is different and may require an atypical approach.

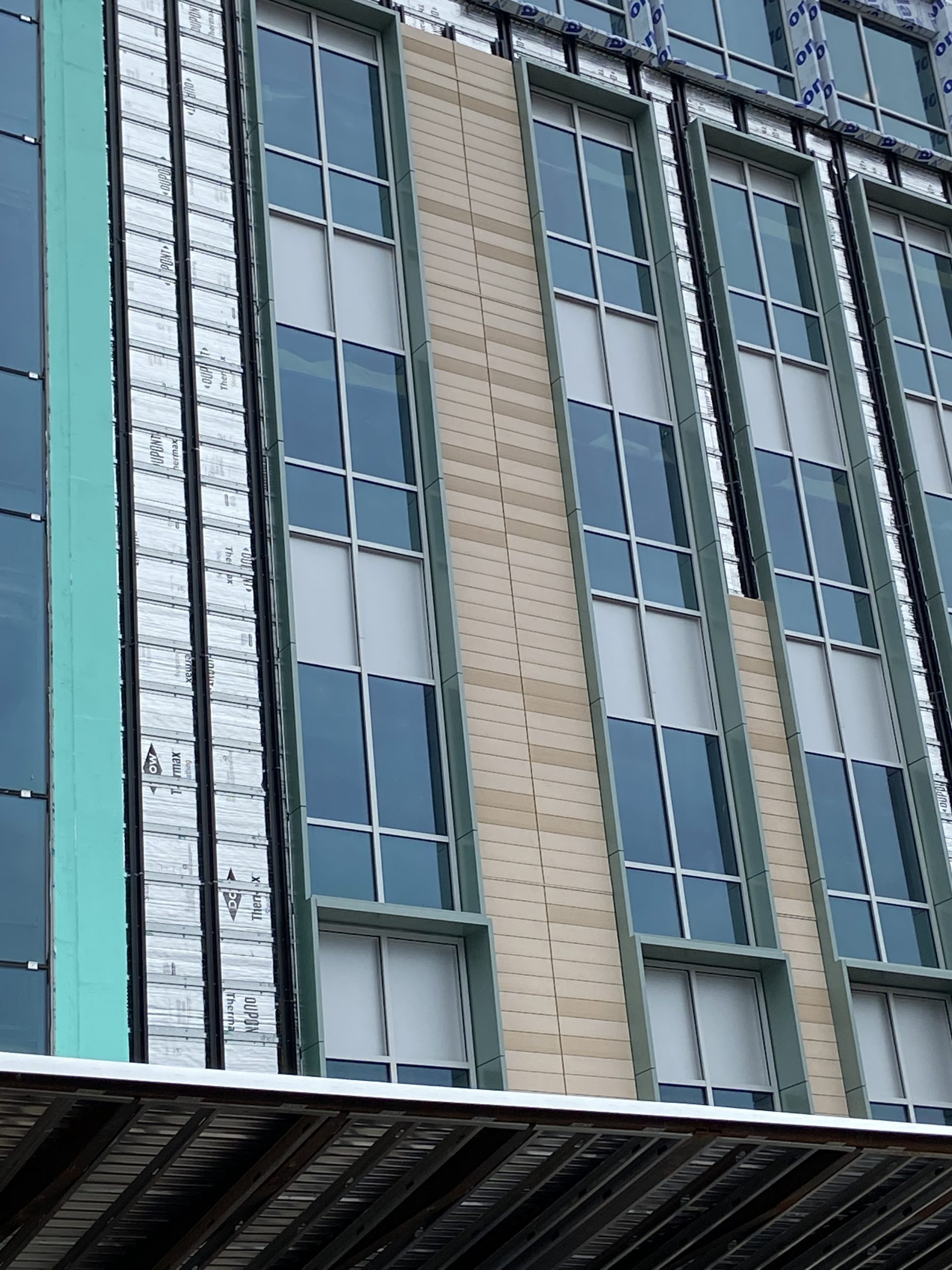

Vertical Terra Cotta Panel with Knight Wall Systems

Vertical terra cotta panels have been accommodated by all of Knight’s systems. The most common application includes a special horizontal carrier rail supplied by the terra cotta manufacturer where the panels are secured to the rail by proprietary clips. This horizontal rail is then attached to a Knight system which would be installed in a vertical orientation (perpendicular to the carrier rail). This will allow for the terra cotta horizontal carrier rails to be installed anywhere they are required for proper support.

A challenge that is regularly encountered, but can be accommodated, is the substantial spacing of the horizontal carrier rails. Terra cotta manufacturers generally attempt to space their rails as far as possible (up to 48″ on-center), however this generally results in massive wind and dead loads (point loads) being applied to the system to which it is attached. These large point loads can be accommodated with slightly tighter spacing of the supporting system or connections behind. Knight typically recommends 16-gauge rails/girts for these applications.

All guidance provided above assumes typical installation applications in which KWS has observed to be the most common methods. Every project is different and may require an atypical approach.

Why Use Knight Wall’s Cladding Support Systems

- Ventilated and drained rainscreen cavity helps to prevent water ingress and other moisture management issues.

- Knight’s systems allow for the addition of exterior insulation to the wall assembly for an increase in thermal performance with minimal thermal bridging.

- Seamlessly transition to other cladding options mounted to Knight’s rainscreen support systems (i.e. metal panels, etc.).

- Knight Wall Systems offers an extended limited warranty for 10-years on their systems when engineered by Knight Wall. The limited warranty will provide both labor and material to remedy any valid warranty claim.