DESIGN ENDLESSLY.

Revolutionize façade panel design and installation with an innovative, pre-engineered solution.

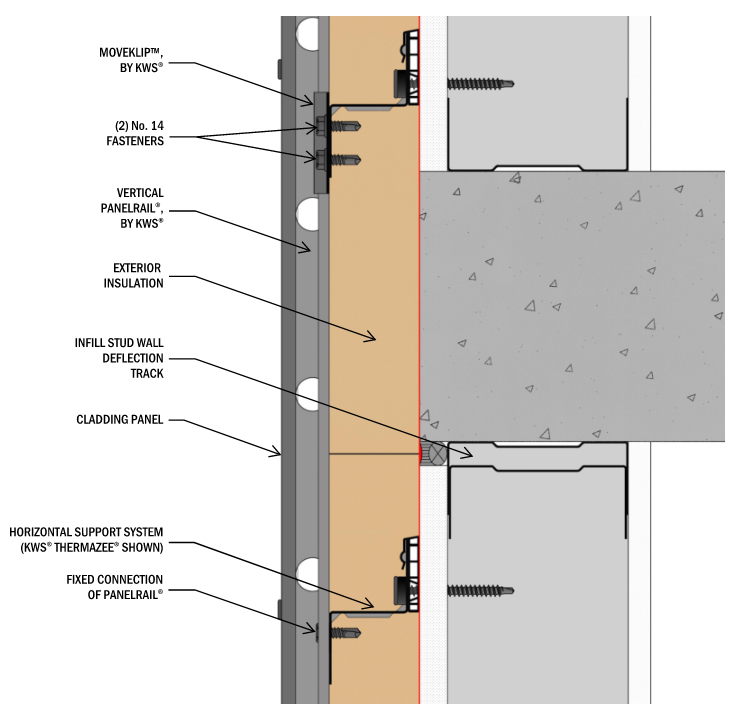

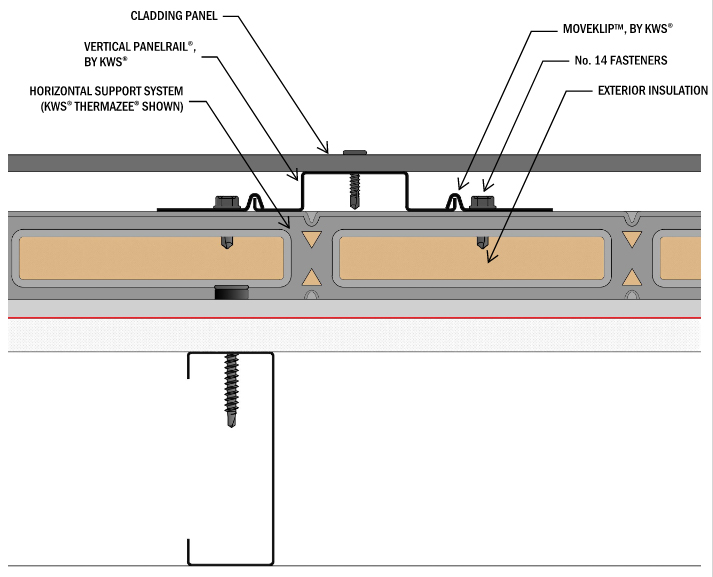

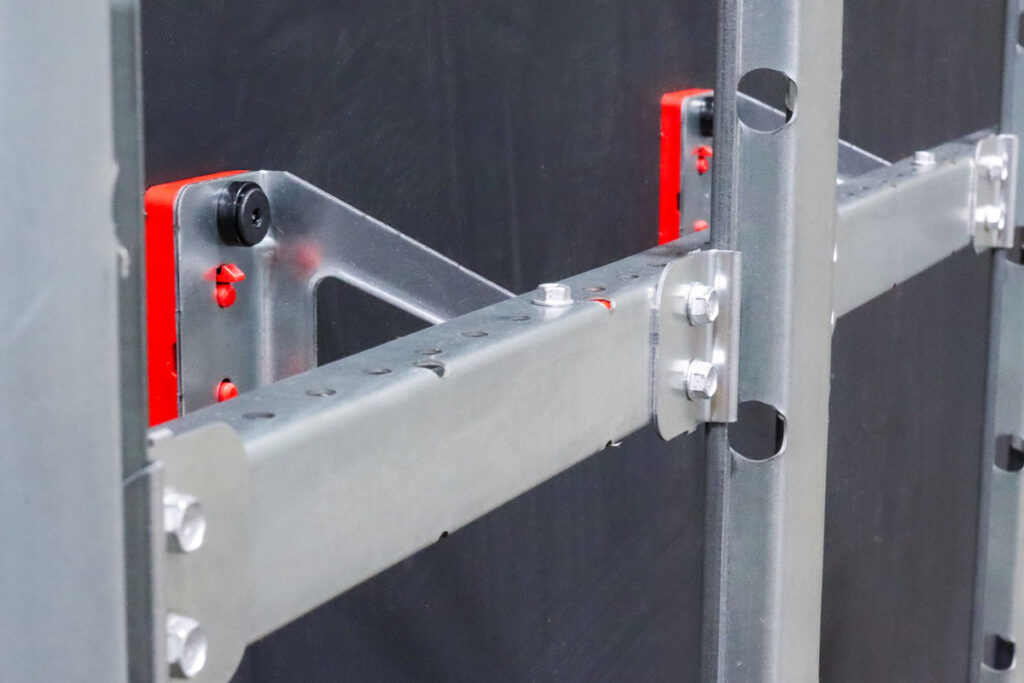

Designed to adapt to your vision, MOVEKLIP™ eliminates panel joints floor by floor, facilitating floor deflection movement in cladding systems seamlessly.

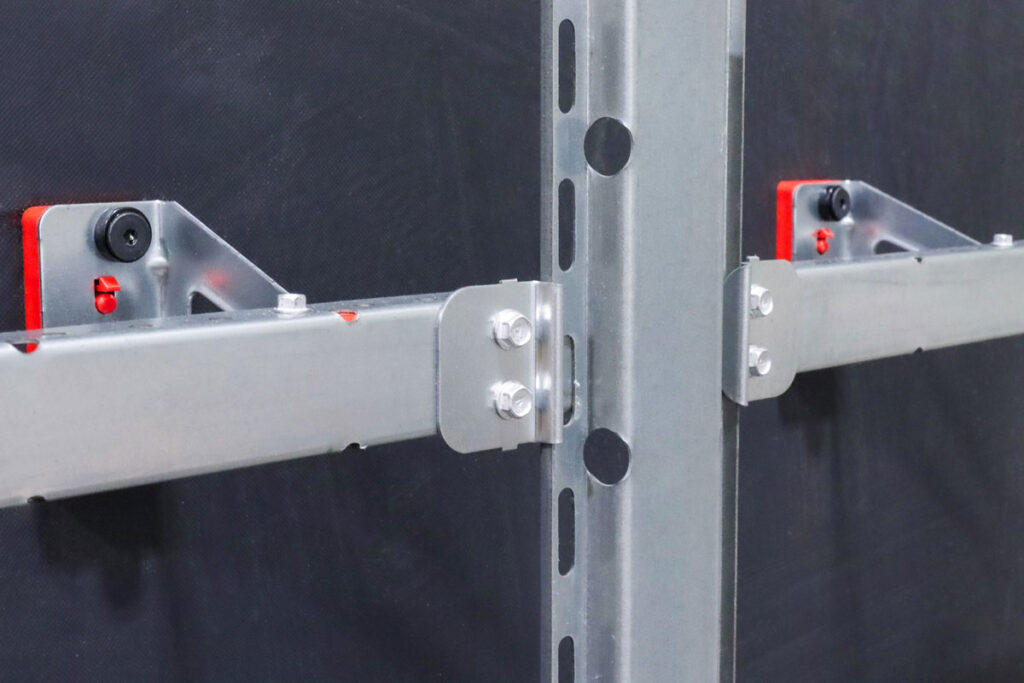

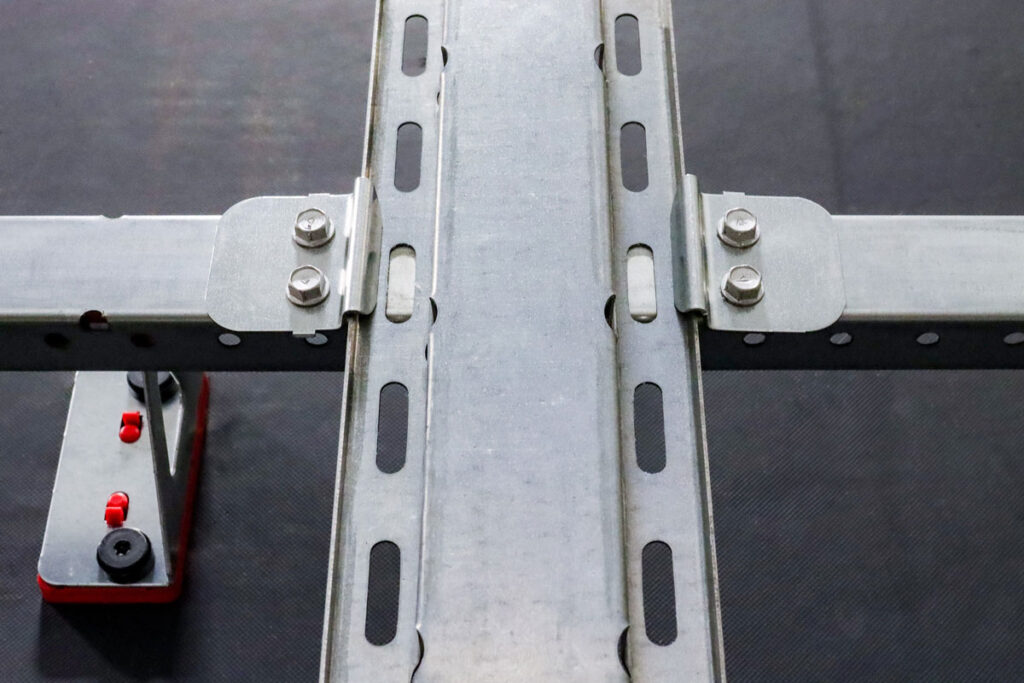

The hook and “clamp” clips require no slotted connections, translating to reduced installation errors, while its simple, installer-centered design enhances productivity. No more overtightened bolts or screws and special tools—installation is effortless, reliable, and compatible with standard PANELRAIL® and diverse claddings such as fiber cement, HPL, and metal panels to name a few. No need for special bolts, polymers, or field modifications, our solution accommodates virtually unlimited floor movement while simplifying every step of the process. Additionally, the connection is 100% non-combustible, ensuring unmatched safety and fire resistance for every project. Formed to protect your façade design.

Patent Pending.

Features

- Eliminates panel joints one floor at a time for seamless design integration.

- Pre-engineered solution facilitates floor deflection in cladding systems.

- No slotted connections reduce the risk of installation errors.

- No overtightened fasteners ensuring proper installation and performance.

- Simple, installer-centered design enhances productivity and reliability.

- Compatible with standard rails and multiple cladding types, including fiber cement, HPL, and metal panels.

- No special bolts, fasteners, polymers, or washers required for installation.

- No special tools, fabrication, or field modifications necessary.

- Allows virtually unlimited floor movement.

- Made of 100% domestic steel with zinc-aluminum-magnesium coating for durability and resiliency.

Benefits

- Streamlined installation process reduces complexity and saves time.

- Minimized risk of errors thanks to simple, reliable components and processes.

- Enhanced productivity compared to traditional methods.

- Cost-efficient as no special materials or tools are required.

- Versatile compatibility supports various cladding systems.

- Installer-focused design makes the process straightforward and hassle-free.

- Strength and non-combustibility ensure safety and resiliency in construction and design.