Design Without Compromise Anchored By Strength and Thermal Integrity.

SEE THE THERMAL LOSS DIFFERENCE:

- KWS® MFI® System: ONLY 7%-20% Loss of R-Value

- Fiberglass Clips: 14%-27% Loss of R-Value

- Aluminum Brackets: 18%-41% Loss of R-Value

- Horizontal Z-Furring: 35%-53% Loss of R-Value

*Lost R-Value percentage will vary based upon exact wall assembly configuration. Values shown assume typical 16″ OC steel studs and 24″ spacing of brackets/rails with varying thickness of insulation.

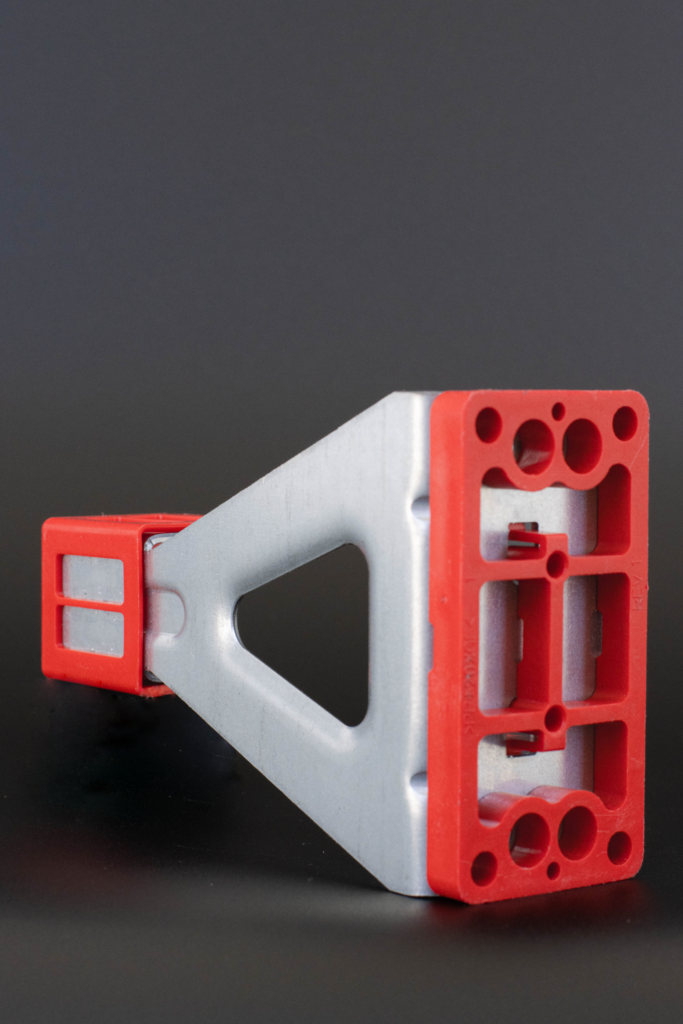

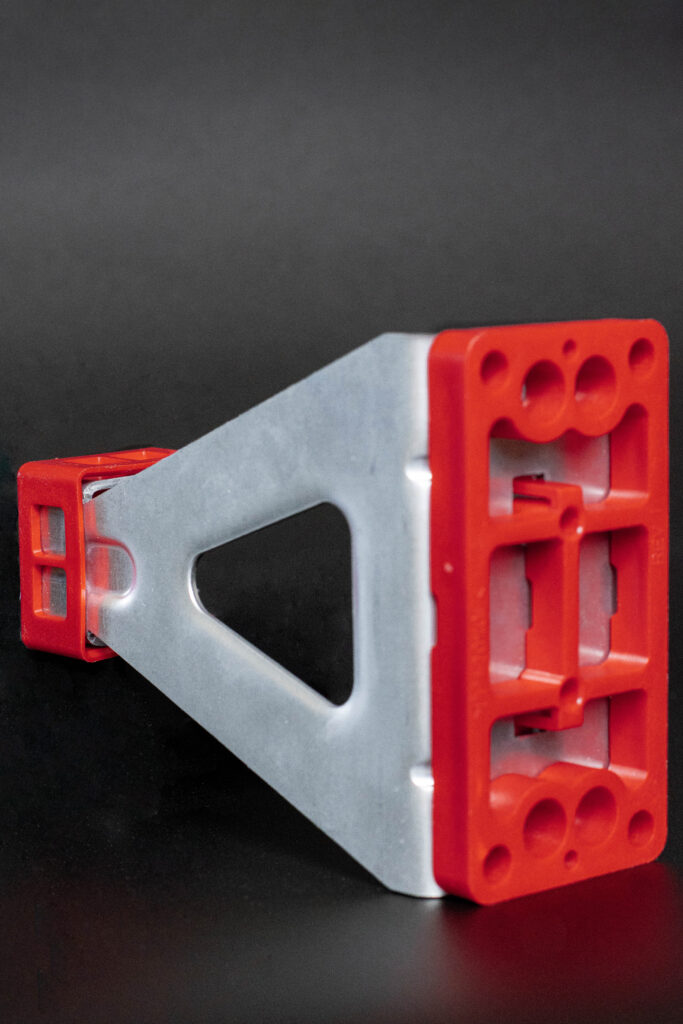

The KWS® MFI® System dramatically reduces the thermal bridging within rainscreen wall assemblies, while providing limitless design options for building facades; combining energy efficiency, façade versatility, and long term sustainability. Being primarily comprised of steel, the MFI® System offers a resilient, durable and non-combustible option to meet today’s high demand.

The MFI® System uses unique thermally isolated intermittent clips – called THERMABRACKET® – that can be spaced all the way up to 32” O.C. They use a unique thermal isolation assembly, called THERMASTOP®, creating one of the most thermally efficient mineral fiber cladding attachment systems on the market today – typically outperforming standard metal clips and rails and even FRP brackets and rails.

The continuous rails attaching to the brackets may be oriented vertically or horizontally. Quickly plumb facades during install with an adjustable rail/bracket connection or use KWS® unique, self-aligning, structural shims. The MFI® System may be used with or without secondary rails for fiber cement, metal panels, terra cotta, phenolic panels or Aluminum Composite Material (ACM) and many more.

View our frequently asked questions for more information.

The MFI® System has two versions: S-Series and D-Series

Custom bracket sizes are available up to 16″ long. See our HD THERMABRACKET® for greater load capacity.

Both series offer the same versatility and thermal performance listed above.

*Spacing is dictated by design wind pressure, cladding weight, deflection requirements and substrate type. Contact KWS for project specific spacing recommendations.

Advantages to KWS® MFI® System Cladding Support

- Brackets can be spaced to 48″ O.C.*

- Rails may be attached to THERMABRACKET® in a vertical or horizontal orientation

- Exterior mineral fiber insulation fits tight around THERMABRACKET® without trimming

- Project specific engineering available

- Limited 10-year warranty available

- High corrosive-resistant Zn-Al-Mg ZM40 coating for a long service life vs. typical G90 Galvanized steel

- THERMASTOP® assembly arrives onsite attached to THERMABRACKET® – No pre-assembly required

- Attach nearly any cladding with easy and efficient installation and detailing

- Wall anchors included

- Minimal thermal bridging

- Accommodates up to 6″ of outboard insulation – standard. Custom available.

- Faster installation: Built-in adjustability easily plumbs old and new walls equating to labor cost-savings

- Pre-engineered and tested (substrate connection detailed per project)

- Ideal for renovations

- Extremely cost competitive compared to typical means of exterior insulation

S-Series

- S: Static – the S-Rail to THERMABRACKET®-S connection is fixed

- S-Rail Cavity Size: 3/4″ or 1″ (+ secondary rails if needed, see typical details and specifications)

- Adjustments for Substrate: use Knight’s supplied ThermaStop shim without sacrificing thermal performance – 1/8″ increments

- THERMASTOP® shim fits square, straight and flat to the back of the THERMASTOP system by means of raised lips that securely lock the shim in-place for maximum structural integrity

- KWS® isolator shim is included with every S-Series MFI® System shipped

D-Series

- D: Dynamic – the D-Rail to THERMABRACKET®-D connection is adjustable

- D-Rail Cavity Size: 1.5″ (+ secondary rails if needed, see typical details and specifications)

- Adjustments for Substrate: rail-to-bracket connection has built in adjustability of 3/4″ for a quick, simple and precise installation

- THERMASTOP® shims may also be used if further adjustment is required.

Options

- SYSTEM DEPTH: See bracket size PDF or custom depths available

- RAIL FINISH: Mill or Black

- RAIL GAUGE: 18-GA or 16-GA – both 50 ksi

- RAIL LENGTH: 120″ Standard or custom lengths available